|

1.

How much water flow will the Cottagepump and Yardpump deliver?

Our 1.375" internal

diameter cylinder will deliver about 18 litres/minute at 3 foot stroke.

Depending upon demand, other sizes of cylinders for other depths may be

introduced. We have a few prototypes and some tooling for a 1.75"

internal diameter cylinder. These prototypes were treadled at 2 foot

stroke to yield 24 litres/minute.

2. How deep down a well can the Pullpump technology reach?

The Pullpumps are NOT suction pumps which are limited to wells less than

32 feet. The initial shuttle that we have for sale is sized for

comfortable treadling from depths of up to 100 feet.

The depth that future smaller sizes can operate from is limited by the

stretching of the polyethylene drop pipe and the pump cable. Wire rope

should be used down deep wells and spliced to rope to run over the

cottage pump pulleys. Increasing its size and switching to 1x19 lay will

reduce the wire stretch very significantly for wells deeper than 100

feet, but even for the Yardpump there must be a joint to a maximum 3/16

7x19 wire to go around the clothesline pulley at the top.

The present size of polyethylene drop pipe stretches 6" from

straight at a depth of 300 feet during the Pullpump cycle. This is

probably the ultimate limiting depth given that one must add the

straightening of residual curving in the wellcasing from the coiling for

shipment.

3. Is my site suitable for the Cottagepump?

The most

suitable site has almost level diggable ground between the wellhead and

the cabin. While the buried PVC pipe can be curved slightly and the rope

still run acceptably inside it, major jogs in plan such as around rock

outcroppings will require additional pairs of CP pulley elbows.

4. Is my waterbody suited to the Flo'Pump?

An

indicator of a good Flo'Pump location is whether the wind ruffles the

surface of the water at the anchoring point. Upwind groups of trees such

as water-loving poplars (cottonwoods) inevitably cause problems and have

to be sacrificed. Also on a small dugout, consider the sheltering as the

Flo'Pump lowers the level in the pond to within 2 feet of the bottom. On

a small pond (with good recharge) the Flo'Pump can be located by three

non-bouyant lines to the shore. The wingtip must not be able to touch the

pond bank so the anchor point must be surrounded by at least 30 feet of

water in all directions when the pond is at its lowest. At a pumping

power (see #6) of 100w averaged over calms, the Flo'Pump will lower an

unrecharged 100' square pond about a metre per week. The Flo'Pump will

tolerate the worst waves in storms from fetches of up to a mile. It is

easy to rig up a winch for the Flo'Pump to carry and set its own anchor

weight, typically 200 lbs. A small row boat is useful for accessing the

anchored Flo'Pump and for towing it to shore or around a lake (with

anchor suspended).

5. Is my well suited to the Flutterwellpump?

The ideal

site has no wind obstructions such as trees or two-storey buildings

nearby, especially upwind against the prevailing wind. The obstructions

above the height of the bottom of the tailvane should be 7 times more

distant than their excess height, or 5 times more distant than their

total width. Wind steadiness of direction can be tested with a ribbon; a

shift of 60 degrees in less than 10 seconds is about the limit for

sustained oscillation.

Keep the Flutterwellpump clear of powerlines and public rights-of-way.

The ideal well casing is steel grouted into bedrock, so that no

foundation is needed. Grouting the casing in also prevents any clearance

space between the hole to bedrock and the casing filling with drilling

mud, which offers little support. A nearby strong point such as a small

tree in the crosswind direction is ideal for handwinching the Flutterwell

Pump up and down.

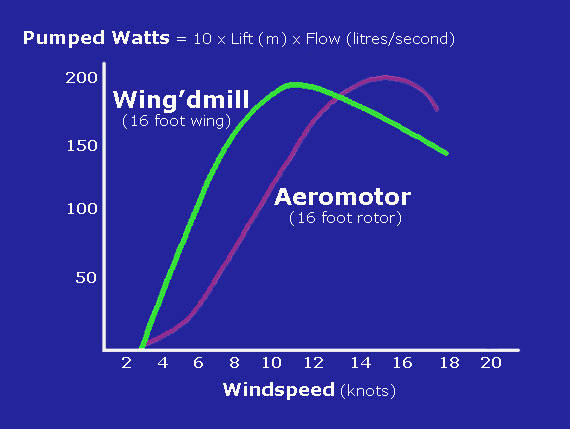

6. How much pumping power do the Wing'dmills have?

The graph

horizontal axis is wind speed at mid-wing in knots= twice the windspeed

in meters/sec.

The

vertical axis is output pumped watts = 10 x flow in litres/second x head

in meters

The peak 250 watts is about 6 times what a human

can sustain on a treadle pump.

There are

many points of caution about use of this graph. First, airports report

windspeeds at 10 m height, typically wingtip for a Flutterwellpump.

Secondly, your site windspeed may be very different than that at the

nearest airport.

The Flutterwellpump and Flo'Pump are suitable for light but steady winds,

with typical winds about 6 knots and mean windspeed about half of that.

The typical multiblade Aeromotor table had to be rescaled to reflect how

it would pump in comparison if it were also setup with a light pump load

for operation in such light winds.

The Flutterwellpump and Flo'Pump can undoubtedly be setup for a slight

multiple of these winds by increasing the pendulum frequency

proportionately. Then the pump load = head x stroke volume must be

increased as the square of the multiple, and the delivered power will be

the increased as the cube of the multiple. However there are limits of

wing strength and pumping speed to be wary of, as well as more subtle

scaling effects ultimately threatening the high wind safety.

In the Flutterwellpump, the wing and pendulum are limited to stay at

least 8 feet above the ground, to always be clear of people or animals.

In the Flo'Pump the wing and pendulum can just scrape the water, so the

maximum angles of swing are the same, and the graphs should be identical.

Wind over water is steadier and stronger; but has less of a gradient,

which detracts a bit from the peak power, but improves the high wind

safety.

7. What different sizes of Wing'dmills are possible?

The

wing'dmill solution is radically outside the paradigm of conventional

small windmills. The Wing'dmills are big and powerful, yet light and

don't need much wind. This is possible because of their inherent

self-protection in storms. Wings have been built from 14 feet to 19 feet

in length and larger sizes are easily possible, at least up to 24 feet.

The construction method and cheap cost of wing materials economically

favour large sizes. But trying to design a small wing'dmill for windy areas

is problematic. Then the effectiveness of gravity versus inertial forces

is diminished in flipping the wing, in returning the pendulum, and down

stroking the pump.

8. What makes the wing'dmills oscillate in moderate winds but not

high winds?

The basic phenomenom is binary flutter.

Binary because the wing 1) can pitch about a spanwise axis less than one

quarter of its chord behind its leading edge, but that axis itself 2)

rolls crosswind as part of the pendulum. The two motions are statically

coupled by the wing being statically imbalanced, specifically tailheavy

about its pitch axis, so that a roll inclination of that axis makes the

wing want to swing its trailing edge to that side. There is also dynamic

"flick" coupling from dynamic imbalance of the wing, as in the

aircraft flutter, which caused many crashes before it was understood.

Thanks to the tailvane, equilibruim is upright with the wing feathering

into the wind. However for a range of windspeeds from light to moderate

this equilibruim is unstable and disturbances by windshifts grow

exponentially into a large amplitude oscillation. It is easy to see how

as the pendulum is slowed by gravity and the pump pull, the wing falls by

gravity and its inertia from being tail-high to tail-low ; which then makes

the wind drive the pendulum back to the other side, and so on..

The wind is actually damping this wing pitch oscillation, just like it

overdamps a windvane released from an angle to the wind so much that the

windvane never overshoots the real wind direction. This wind damping of

pitch increases with windspeed whereas the pitching torque on the wing

due to roll and gravity doesn't. So the amount of wing pitch steadily

decreases with windspeed, limiting the wing angle of attack and its

stress to a safe level.

Ultimately as the wind rises, its damping of pitch is just too much and

the feathered equilibruim becomes stable. The wind also raises the

frequency of pitch response which becomes much greater than the roll

frequency of the pendulum, upsetting the resonance. However just as in

the windvane situation , the damping effect is the dominant one.

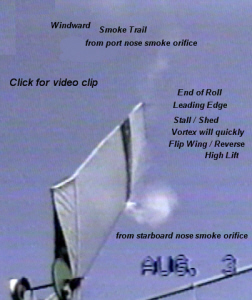

9. What makes the wing'dmills so efficient in light (but steady)

winds?

As the wing transverse speed builds relative to the light windspeed,

aerodynamic non-linearities greatly enhance the energy capture of the

starting mode of high pitch/roll with only 65 deg phase advance .

For a laminar light wind increasing in proportion to the height above

the roll axis at the top of the vegetation layer; the apparent wind is at

uniform angle of attack all along the wing and uniform multiple of the

true wind, peaking at 3 for 9 times the dynamic pressure.

The fresh wing boundary layer every swing dynamically delays stall

(completely for sections thicker than NACA 0012) to allow very high lift

(and L/D) coefficients as the pitch trace saturates into a square wave of

+/-90 deg.

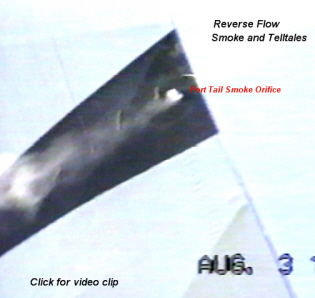

At the end of the roll swing, the wing begins to back up due to the

small phase shift. Despite the sharp edge at extreme angle to the true

wind, the new reverse boundary layer remains attached right back to the

nose which sheds a huge vortex away from the swept area. The growing

reverse lift will be centered near the 3/4 chord point for a rapidly

increasing moment to start flipping the wing about the pitch axis. Then

the pitch mass imbalance torques, large at moderate pitch angles relative

to normal lightwind torques can effect the complete reversal of the pitch.

It seems the new wing circulation is unchanged in this rapid 180 deg

flip, and that the initial shed vortex carries away almost all the entire

change in circulation.

The strong increase of such dynamic flip impulses along the span vs

the uniform distribution of pitch inertia (mainly from the added mass and

the trailing edge) explains why high torsional rigidity had been found to

be critical in power tests of 6 full-scale wings.

|