|

Air compressing with the Wing'd

mills

1.Simultaneous air compressing to same pressure at the

windmill as the pumped water

When the Wing'd mills are pumping water a distance

horizontally either ashore and/or overland, it reduces the flow friction in

the pipeline to smoothout the pump pulses with an air cushion. The main

complication with standard air chambers is the loss of air by absorption

into the pressurised water, which requires airbags or diaphraghms or manual

replenishment.The Flo’Pump has an inlet

at the waterline top of the cylinder that snifts in air behind the piston weight falling through the water to

automatically replenish the built-in

air and valve chamber above the

cylinder. Excess compressed air can be tapped for a secondary use, normally

aeration of the pond bottom. If the Flutterwell

is also pumping through a pipeline a snifter valve below a check valve

entry into a simple bag-less air chamber at the wellhead snifts air as the watercolumn regresses on the

downstroke of the PipePump. This gives output

air to water in a 1/3 nominal (atmospheric) ratio.

2. Dedicated Air Compressing with additional battery

charging

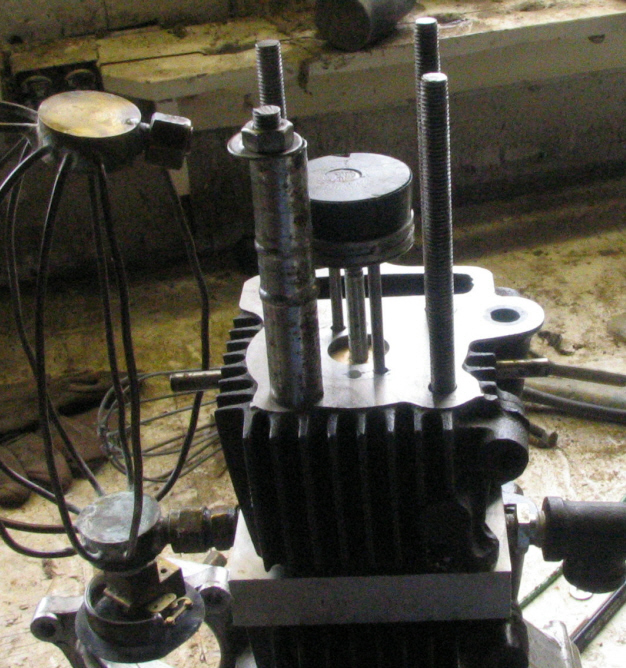

This design is based on the Honda 50cc motorcycle engine

Its standard tierod cylinder and head mounting makes it easy to extend the

cylinder with the high pressure (HP) valve head, and then a cored block for

the small diameter high pressure cylinder, then a normal block for the LP

cylinder and finally the LP head. The most difficult part is attaching the

extension piston rods to the top of the original delicate aluminum piston.

(sans oil rings).

The HP and LP pistons are interconnected by a central rod and used the

standard cup seals. However the cup dead space was filled with plastic plug

to minimise the knocking and jamming from minor bottoming out for the

efiiceint minimum dead air space. The cam chain is rerouted to directly

drive the engine oil pump and an oil path created to the high side of the

top LP cylinder just under the cup lip BDC.

The previous experience was that standard compressor reed valves had to

be adjusted most carefully to minimise high static leaking. Presumably they

are demanded by the high rpms and temperature buildup of standard

compressors. Here with intermittent operation at lower peak rpm and the

certainty of good cooling in the wind, and finally the intercooling, the

temperature should stay below 300F and the tolerance of high temperature if

not standard O-ring seals. These were used on the seats of all 4 valves, 3

of which were sprung brass sliders in the solid aluminum heads with only

the input HP valve remaining as a leaf

because of space constraints.

The cylinders were separately bench tested and these valves developed to

achieve very low static leaking. Nonetheless in the assembled unit the

Intercooler loses static pressure to the engine space by leaking around the

HP piston cup. To minimise this loss of air in intermittent operation the

intercooler has to be optimised for high heat transfer but low internal

volume and low flow friction using parallel connection of several fine bore

copper tubes. The standard crankshaft seal in the engine will not stand

significant pressurisation.

In 2005 an alternator was tested directly connected to

this stub of the crankshaft and heavy pulses of current delivered at 12v

with no additional noise. In fact the principal noise are the compressor

strokes, so proving that even a spur gear train in an enclosed oil bath is

much quieter than the previous external ring gear driving a ratcheting

pinion on the alternator. However now the alternator inertia is tapped by

the main compressor load as well, so the alternator delivered voltage and

power are both reduced. Without electronic load switching and just ordinary

voltage regulation, an alternator is a constant power load and so cannot be

primary for the Wing'd Mills.

|